Technical Information

Metallic Glass

High strength, low spring constant.

Metallic glass (MG) has unique mechanical properties, combining high strength and low Young’s modulus. By applying MG to the fabrication of fastening bolts, high strength and low spring constant bolts were obtained. The bolts are manufactured by cold thread rolling (CTR) which has been considered to be difficult to apply to the fabrication of MG parts. This process provides MG bolts with toughness. This has led to the realization of mass production. The high strength and low spring constant provide the special properties of tightening the components gently and high resistance against bolt loosening.

Cold working processes enhance mechanical properties of metallic glass

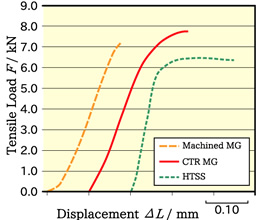

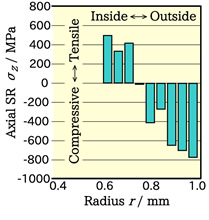

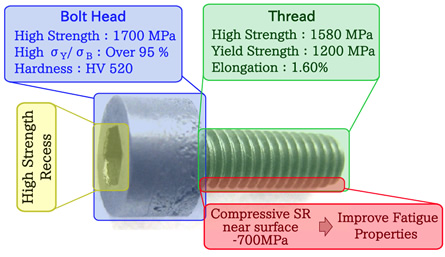

Metallic glass bolts are 30% greater in strength than high tension steel bolts (Fig. 1). The metallic glass bolts formed by cold thread rolling reveal toughness which is not observed in machined MG bolts. It is considered to be the result from the residual stress (SR) due to the cold forming process (Fig. 2). Moreover, this compressive SR near the surface is expected to contribute to the improvement of fatigue properties. Furthermore, the bolt head remains high in yield strength, which leads to the high endurance of the recess of the bolt for repetitive use.

-

Tensile load axial displacement curve

-

Distribution of axial residual stress in a CTR MG bolt

-

Characteristics of Zr55Cu30Al10Ni5 CTR MG bolt

Excellent fastening feature, contributiong to the light weight and down sizing

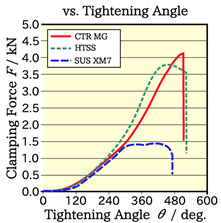

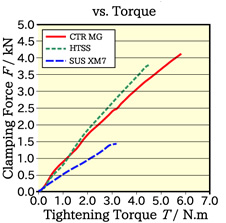

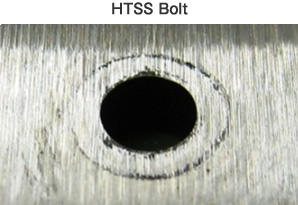

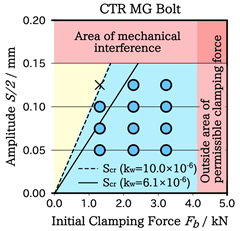

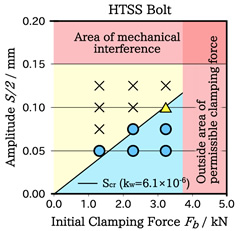

MG bolts realize greater clamping force and tightening torque than high tensile strength steel (HTSS) bolts, which leads to precise control of the clamping force (Fig. 4). The bearing face exhibits a smoother contact area than HTSS-bolts due to the reduction of maximal contact pressure (Fig. 5). In addition, it came to light that MG-bolts have high resistance against bolt loosening, which is the critical feature for fastening parts.

-

Features of clamping force

-

View of the contact face on the fastened parts with bearing face of bolt after bolt tightening test.

-

Results of bolt loosening test by oscillation of fastened parts in perpendicular to the bolt axis.

Main application