Technical Information

Medical Equipment Manufacturing Industry

No hazardous elements to human body

Hight elasticity

Hight flexible

Our current development project is designing brand new products for the newest techniques in the medical field.

The medical field is becoming more sophisticated and diverse so Maruemu Works is contributing to a healthier and happier life for people by developing these new medical parts.

We have achieved this by applying our original techniques acquired by manufacturing of screws to the new field. Complying with our company’s concept, we have successfully made the products to improve the quality of life for people in general.

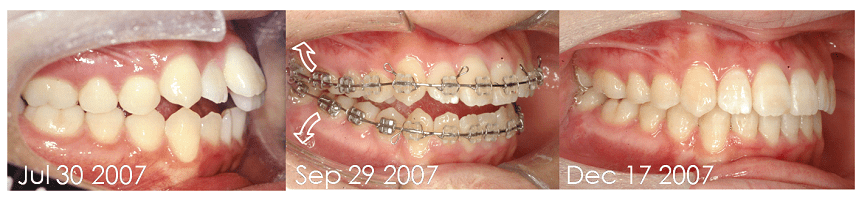

Orthodontic wire

Orthodontic therapy is prevalent overseas, especially in the US. At the present time, this kind of treatment has become popular and has caught our attention as people become mentally and physically stressed due to wearing orthodontic braces. We want to resolve this problem by resolving the aesthetic problems and satisfying the patient’s needs. Usually, Orthodontic therapy requires long term treatment. The accompanying pain and discomfort are a physical and mental burden on a patient. Considering these circumstances, Maruemu Works initiated the development of the orthodontic wire made of Ti-Nb based beta titanium alloy, GUMMETAL, which exhibits excellent orthodontic abilities and has biologically friendly features. Although the wire is difficult to form the desired shape and stability in the manufacturing process due to its special mechanical properties, Maruemu has overcome these difficulties by using its original methods for wire drawing and wire bending. The development of the orthodontic wire, GUMMETAL, which reduces both treatment time and pain, has been achieved. We started mass production and sales domestically from June 6th 2010. The product is available and scheduled for export to the US and Europe in 2013.

Characteristics of GUMMETAL orthodontic wire

GUMMETAL is beta-titanium alloy developed in the Institute of TOYOTA Central Laboratory, a think-tank of the TOYOTA group. The name, GUMMETAL, comes from the fact that the mechanical characteristics resemble rubber, or GUM. It features extremely low Young's modulus and high elasticity in bending in addition to the high strength. Moreover, the mechanical features of the minimal work hardening contribute to the resistance against bending fractures. In addition it consists of biologically friendly elements, so the safety features are ensured.

Thanks to thses characteristics, GUMMETAL orthodontic wire has a high potential to cut down the treatment time and to relieve the pain of patients.

Provided by Institute of Toyota Central Labopratory

The chemical composition and mechanical properties of biochemical metals

- biological material

- Principal alloy

- Alloy elements

- Young’s Modulus

- Tensile strength

- Noble metal

- Palladium

- Au-Ag-Pd

- >250

- 900

- Stainless steel

- SUS316

- Fe-Cr-Ni-Mo

- 200

- 860

- CoCr alloy

- Elgiloy (green)

- Co-Cr-Ni-Mo

- 181

- 1,956

- Titanium

- Pure titanium

- Ti

- 110

- 420

- Ni-Ti alloy

- Nitinol

- Ti-Ni

- 105

- 700

- α+β-Ti alloy

- ASTM F136

- Ti-Al-V

- 85

- 860

- β-Ti alloy

- GUMMETAL

- Ti-Nb-Ta-Zr

- 60

- 1,100

Chromium Nickel, Vanadium