Technical Information

Magnesium Alloy

Lightweight High strength Heat resistance

Magnesium (MG) alloy has the lowest specific gravity of all structural alloy metals. The fastening bolts made of the magnesium alloy are not only lightweight but provide lots of advantages in terms of fastening properties in cases of tightening the magnesium alloy component. These merits are obtained because bolts and fastener components are alike in terms of mechanical and chemical properties. Therefore, magnesium structural parts provide the best performance when tightened by magnesium alloy bolts.

Maruemu Works started mass production of Mg alloy bolts made of AZ31, popular magnesium alloy, in 2004. As a leader of Mg bolts manufacturing, Maruemu developed new Mg alloy bolts with higher strength and high heat resistance. The AZX912 bolt was developed under a grant from the Government, Ministry of Economy, Trade and Industry. Mg alloy bolts fasten Mg parts tightly but gently.

Mechanical properties

-

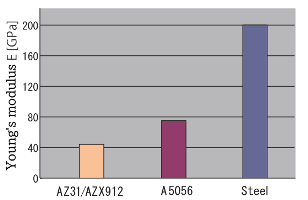

Elastic constant

Mg exhibits a very low Young's modulus compared to other metal alloys. The male bolt with the same Young's modulus as the fastened part is ideal to correctly engage the female thread. Mg alloy bolts protect the female thread fabricated in precious Mg parts against fractures due to the uneven loading.

-

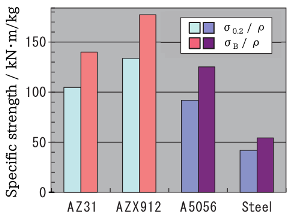

Specific strength

Specific strength represents material's strength divided by its density. This value is nearly equivalent to the bolt tensile strength divided by its density. As the specific strength of AZ912 bolt is three times greater than that of soft steel bolts, AZX912 bolts contribute to the reduction of weight by 66 %. For example, total weight of AZX912 bolts becomes one third of that of soft steel bolts to bear an external load by fasteners.

-

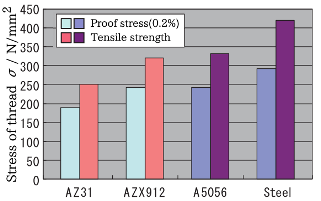

Tensile strength of bolt and its proof stress

AZX912 bolts exhibit the equivalent strength of A5056 Al alloy bolts. Presently, we are developing new Mg alloy bolts with much higher strength than A5056. We will continue the development for new reliable items to respond to the expectation of customers.

Chemical composition

- Al

- Zn

- Mn

- Fe

- Ni

- Cu

- Si

- Ca

- Mg

- AZX912

- 9.22

- 0.60

- 0.31

- ≦0.005

- ≦0.005

- ≦0.05

- ≦0.1

- 2.08

- Bal.

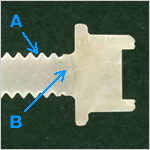

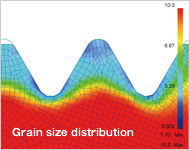

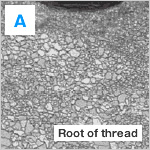

Fine grains created by thread rolling

By using wrought Mg rods, Mg bolts reliability is ensured. Moreover, thread rolling at optimal temperature and velocity creates fine grains near the root of the thread in which higher stress is induced during fastening. The average diameter of the grain is controlled to 5-6 mm throughout the process of dynamic re-crystallization. It contributes to the high strength and toughness.

Bolt loosening

The high resistance against bolt loosening in Mg alloy bolts was examined by a reliable bolt loosening test. Therefore, Mg alloy bolts are able to be tightened with lower initial clamping force than other material bolts. It is mainly due to its Low Young’s modulus.

G. Hibi et.al: JSME annual meeting, 2010(4), p137-138

Fastening properties

Mg alloy bolts exhibit higher clamping force than Al alloy bolts regardless of the strength of the bolts. It is due to the favorable surface properties of Mg bolts. This feature contributes not only to reliable fastening but also to resistance against bolt loosening.

(S. Hasimura, et al.: Journal of Solid Mechanics and Materials Engineering Vol.5, No.12, 732-741)

Items and options

AZX912 … Please contact our sales department

* Regarding shape of bolt head, recess, and surface treatment, please contact us

* Please contact us if you need surface treatments under the specific environment.on

Application

-

Transportation industry

EV, HV

Instrument panel

ECU

Aerospace

Railway vehicle

Motorcycle

-

Electric devices

Smart phone

Rap top computer

Digital camera

Heat sink

Optical parts

Audio apparatus

-

Miscellaneous applications

Robots

Health and welfare apparatus

Medical devices

Electric appliances

Radio controlid

Leisurer goods