MARUEMU WORKS

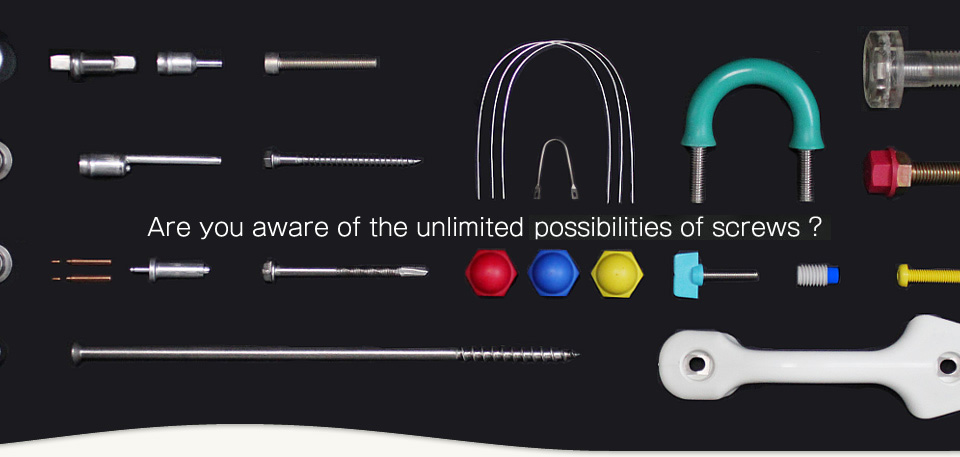

Maruemu works is at the top of Future-oriented Manufacturing Companies. Our work ranges from manufacturing and selling whole fastening parts to developing new products in various fields in particular, the Medical field. Our die-making section enhances our development by shortening the development time to meet customer demand.

As a pioneer of the fastening industry, we have brought forward new products, such as stainless steel screws since 1952 and Engineering Plastics since 1992 In the 21st Century we developed various Titanium Alloy bolts (2004-2006), Magnesium Alloy Bolts (2004-2009) and unique, versatile Metallic Glass Bolts (2008-…..). These are mainly formed by special plastic working Processes to obtain high productivity with minimum material loss and cost reduction.

High Strength, High corrosion resistance, light-weight, environmentally friendly and recycling have become our main target for new fastening parts. In addition, we started manufacturing medical parts after fundamental research and development with the collaboration of Research Institutes of both Universities and Companies. We position ourselves in the Medical field depending on what our technology can contribute to the most successfully in the future.

Our goal is to challenge any new products that our customer requires and achieve this through communication and collaboration with the customer.

| COMPANY | Maruemu Works Co., Ltd. |

|---|---|

| LOCATIONS | 4-7-12 Nozaki, Daitou, Osaka, 574-0015, Japan |

| PHONE NUMBER | +81-72-863-0122 |

| ESTABLISHED | May 1.1927 |

| PAID-IN CAPITAL | 157,850,000 JPY |

| NUMBER OF EMPLOYEES | 200 |

TECHNICAL INFORMATION

Medical Equipment

Presently, we are developing new products for the medical field.

We are applying our original techniques acquired by manufacturing of screws to the new field. Complying with our company’s concept, we are aiming to make the products to improve the quality of life for people in general.

The medical field is becoming more sophisticated and diverse so Maruemu Works wants to contribute to a healthier and happier life for people by developing these new medical parts.

Metallic Glass

Metallic glass (MG) has unique mechanical properties, combining high strength and low Young’s modulus. By applying MG to the fastening bolts, high strength and low spring constant of bolt are achieved.

We were successful in manufacturing the MG bolts by cold thread rolling (CTR) which had been difficult to apply to the fabrication of MG parts. In addition, the process provides MG bolt with toughness as well as a method of mass production. Moreover, it becomes clear that the high strength and low spring constant contribute to high resistance against bolt loosening.

Magnesium Alloy

Magnesium alloy has the lowest specific gravity in all structural alloy metals. The fastening bolts made of the magnesium alloy are not only lightweight but provide lots of advantages of fastening properties in case of tightening the magnesium alloy component. This is widely used in many fields. The merits are obtained because bolts and fastener components are alike in terms of mechanical and chemical properties. Therefore, magnesium structural parts provide the best performance when tightened by magnesium alloy bolts. Mg alloy bolts fasten Mg parts tightly and gently.

DETAIL

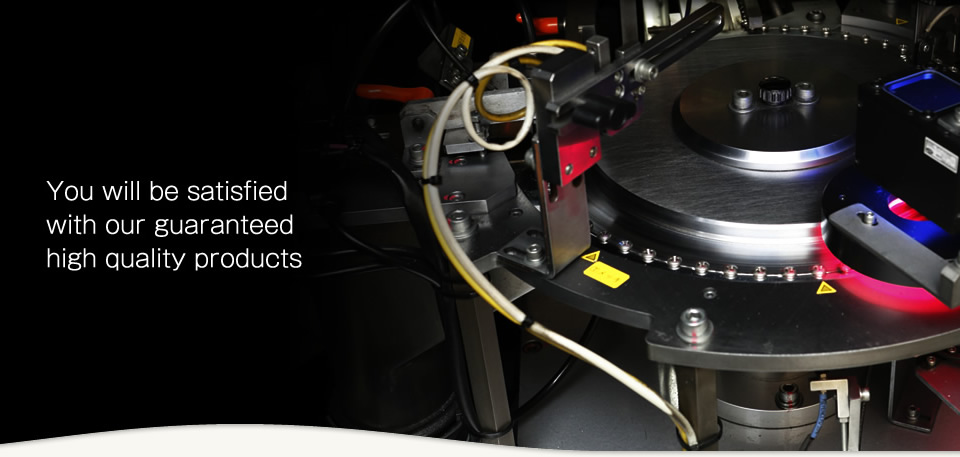

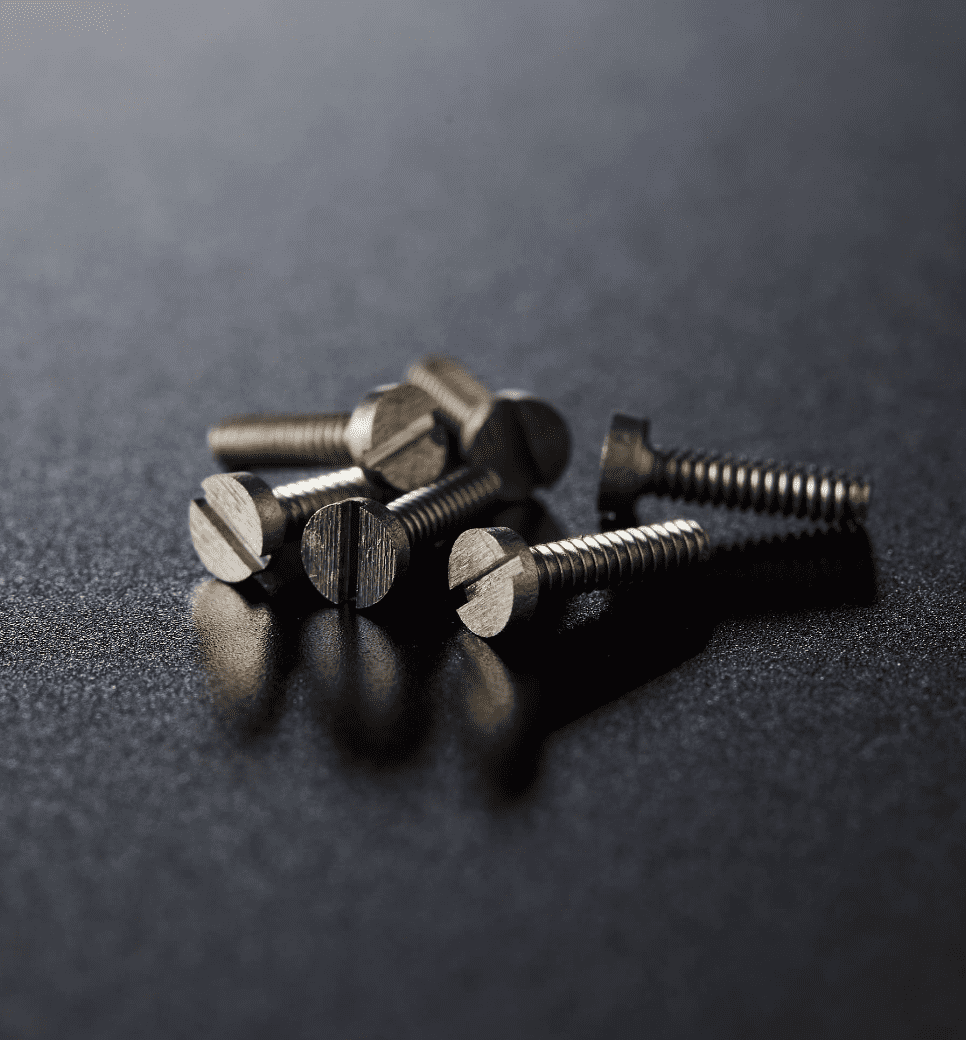

NSSC550

NSSC550 screws are martensitic grade with remarkably enhanced quench hardening.

1. High Strength :

2. Super Toughness :

3. High corrosion resistance :

*NSSC550 was developed by Nippon Steel Stainless Steel Corporation.

ISO CERTIFIED