Technical Information

NSSC550

NSSC550 screws are martensitic grade with remarkably enhanced quench hardening.

1. High Strength :

Achieves high fastening power and no change in thread shape during tapping due to high centre hardness.

2. Super Toughness :

Achieves excellent high toughness by using an appropriate combination of components.

3. High corrosion resistance :

Superiority to the standard SUS304 in corrosion resistance achieved by the appropriate addition of Cr, Mo and N, as well as the control of trace elements.

* NSSC550 was developed by Nippon Steel Stainless Steel Corporation.

Products

Ingredients

- C

- Ni

- Cr

- Mo

- N

- 0.10-0.20

- 1.00-2.40

- 12.50-14.00

- 1.80-2.30

- 0.50-0.15

* Source : Nippon Steel Stainless Steel Corporation

Physical properties

- Longitudinal elastic modulus N/mm2

- Transverse elastic modulus N/mm2Transverse elastic modulus N/mm2

- Density g/mm2

- Thermal expansion coefficient x10-6/℃

- 2.05×105

- 7.94×104

- 7.75

- 11.5

* Source : Nippon Steel Stainless Steel Corporation

Mechanical properties

- Tensile strength N/mm2

- Shear Strength N/mm2

- Surface hardness HV

- Core hardness HV

- Head toughness test

- 1650

- 1100

- 550

- 515

- EXCELLENT

*Source : Marue

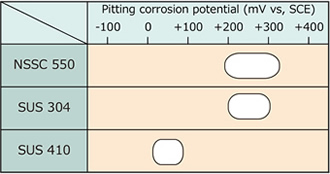

Corrosion resistance

Pitting corrosion potential

* Source : Nippon Steel Stainless Steel Corporation

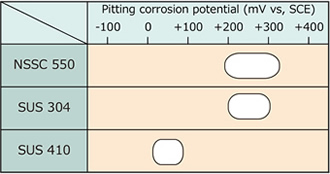

Pitting corrosion potential

* Source : Nippon Steel Stainless Steel Corporation

Salt spray test (ISO9227, 1000h)

SUS410

NSSC550

* Source : Maruemu Works Co., Ltd.

* NSSC550 series have a “V” on the head as a mark.

NSSC550 also got the same result by Kestenich (Sulfur Dioxide) test (DIN 50018, 20cycles).

Salt spray test (ISO9227, 1000h)

SUS410

NSSC550

* Source : Maruemu Works Co., Ltd.

* NSSC550 series have a “V” on the head as a mark.

NSSC550 also got the same result by Kestenich (Sulfur Dioxide) test (DIN 50018, 20cycles).

Precautions